NONCONTACT ROTARY TORQUE SENSORS

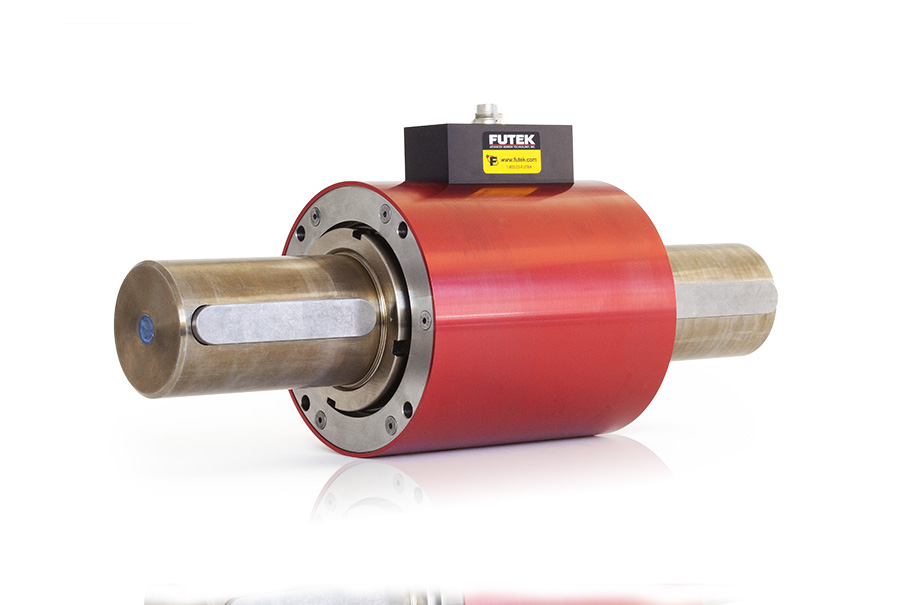

The TRS705 is a Non contact shaft to shaft with encoder Rotary Torque Sensor. This particular model is available in a wide capacity ranging from 8.9in-lb. to 8,850in-lb. FUTEK's Non contact Torque Sensor offers a unique solution for torque auditing and automotive applications.

Rotary Shaft Digital NonContact Torque Sensor HITEC Sensors

This non-contact rotary torque sensor is an excellent choice for dynamic applications with higher lifespan as it is durable and low maintenance. The design allows for overload protection for up to 150% of the rated output. Made to be accurate. Due to its high stiffness and low inertia, TRS600 has a nonlinearity of ±0.2% of rated output and is.

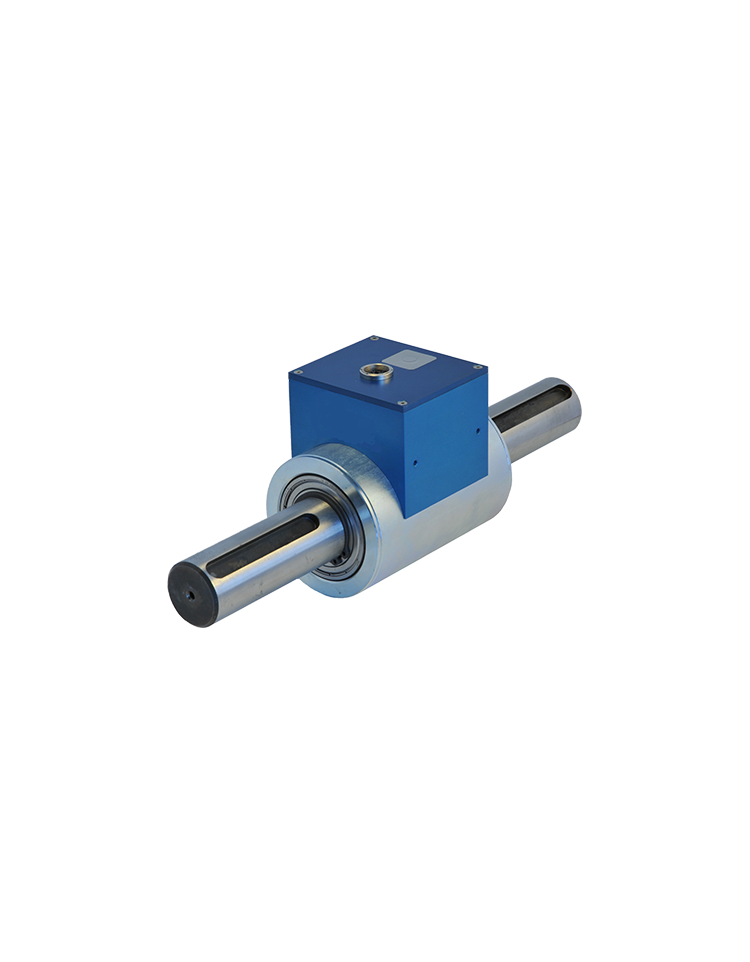

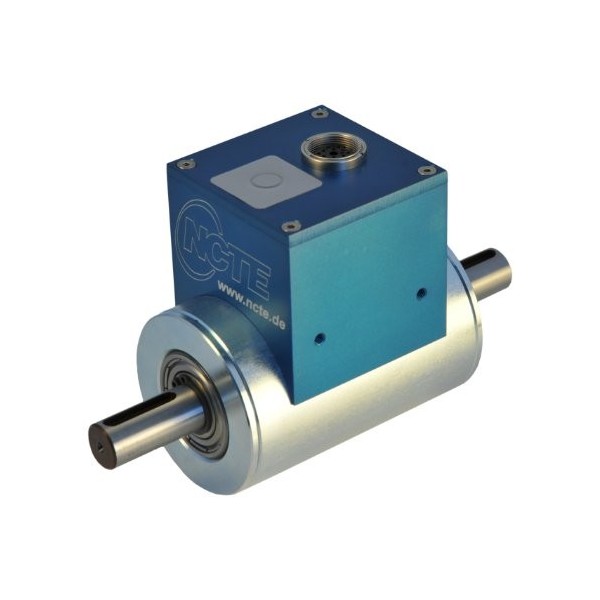

NONCONTACT ROTARY TORQUE SENSORS

Rotary Shaft Digital Non-Contact Torque Sensor. These sensors are designed to measure rotating drive torque using a conventional shaft-to-shaft configuration for in-line placement. The unique design incorporates a digital non-contact wireless system that provides power to the rotating electronics mounted on the shaft and transmits the signal back to the receiver in digital format.

Non Contact Torque Sensor Non Contact Rotary Torque Sensor with Encoder

The FF425 non-contact rotary flange to flange torque sensor has 11 standard torque ranges. The torque sensor offers very high accuracy, operational stability, high signal resolution and wide range of signal outputs across the whole range of torque from 0-100Nm and up to 30,000Nm. Fully Non-Contact Transmission and Hardware; Accuracy: 0.1%

Rotary Torque Sensor, NonContact, 5050000 Nm

Non-Contact Level Sensors. Non-Contact Level Sensors. Level Switches. Level Switches. Flow Instruments. Flow Instruments. Flow Measurement Accessories.. Shaft-to-Shaft Rotary Torque Sensors with Optional Encoder 0 to 200 in-lb, 2.0 mV/V Output. 5.0 (1) Click and hold to zoom. Data Sheet (PDF) $4,845.50 $ --Item# TQ513-200

Non Contact Torque Sensor Rotary Torque Sensor shaft to shaft with

High accuracy non-contact rotary torque sensor, inline torque transducer & torque Measurement Meter with rotating torque measurement from 3nm to 60 knm.. Call us on +44 (0) 1983 282834 or reach out via our contact form. Rotary Torque Sensor. M425 rotary torque sensor with keyway shafts offers high accuracy of 0.1% and torque measurement.

Rotary Torque Sensor, NonContact, Shaft to Shaft, 0.05300000 Nm

General purpose, high rotating speed, non-contact rotary torque sensors with square or round shaft. o Bidirectional o Maintenance free o Round or square shafts (see drawing) o Measurement range up to 100 N·m o Max. rotating speed: - Square shaft: 5 000 rpm - Round shaft: 10 000 rpm

Serie 4000 NonContact Rotary Torque Sensor From +/ 50 to 2000 Nm

FUTEK's Rotary Torque Sensor - Non contact shaft to shaft with Encoder offers a unique solution for torque auditing applications. The TRS805 Non Contact Torque Sensor is available in a wide capacity range of 0.2 Nm - 5,000 Nm and has a high speed range of up to 50,000 RPM, thus making it capable to support a wide range of applications..

NonContact ShafttoShaft Rotary Torque Sensor TRS600 FSH01998

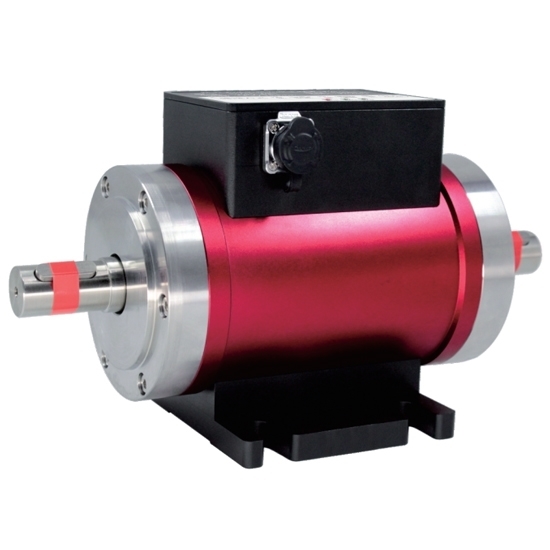

Rotary, Non-contact, Amplified Torque Transducers. Non-contact, amplified torque sensors. Shaft rotary and square drive options.. Non-contact amplified rotary torque sensor. 500 Nm to 2,000 Nm capacity range. < 0.25 accuracy. ±0.15 % rated output non-linearity. Model 1754. You can only request up to 6 free samples. Please remove one or more.

Noncontact Rotary Torque Sensor 0.1Nm 0.2N*m 0.5Nm 1N*m 2Nm 3Nm 5Nm

Rotary, Non-contact, Unamplified Transducers. Shaft, flange, and special torque transducers. Capacities of 0,35 Nm to 7 Nm, 5 Nm to 11300 Nm, 225 Nm to 11300 Nm, and 50 in-lb to 10000 in-lb. Specialty options includes: foot mount, extended speed, very low linearity and hysteresis

NonContact Rotary Torque Sensor TRH605 Metromatics

FUTEK's TRS605 Rotary Torque Sensor - Non contact shaft to shaft with Encoder offers a unique solution for torque auditing applications. The TRS605 Non-Contact Torque Sensor - Shaft Torque Sensor with Encoder is available in a wide capacity range and utilizes strain gauge technology.

QTA137 Custom Non Contact Rotary Torque Sensor with External Amp

Model 1600 is a line of rotary transformer torque sensors often ideal for test installations running long-term durability testing. Non-contact nature of the signal transfer virtually eliminates the need for maintenance. High overload protection with high signal output helps prevent potential damage to the sensor.

NonContact ShafttoShaft Rotary Torque Sensor TRS600 FSH01998

The principle diagram for a non-contact sensor is shown in Figure 2. The EEG signals that are to be monitored and analyzed, in order to determine the states of fatigue and drowsiness, are: Alpha: studies have shown that for an awakened person, the presence of alpha waves indicates relaxation. Alpha waves are in the range of 8 Hz to 12 Hz and.

NonContact SquareDrive Rotary Torque Sensor with Encoder TRD605

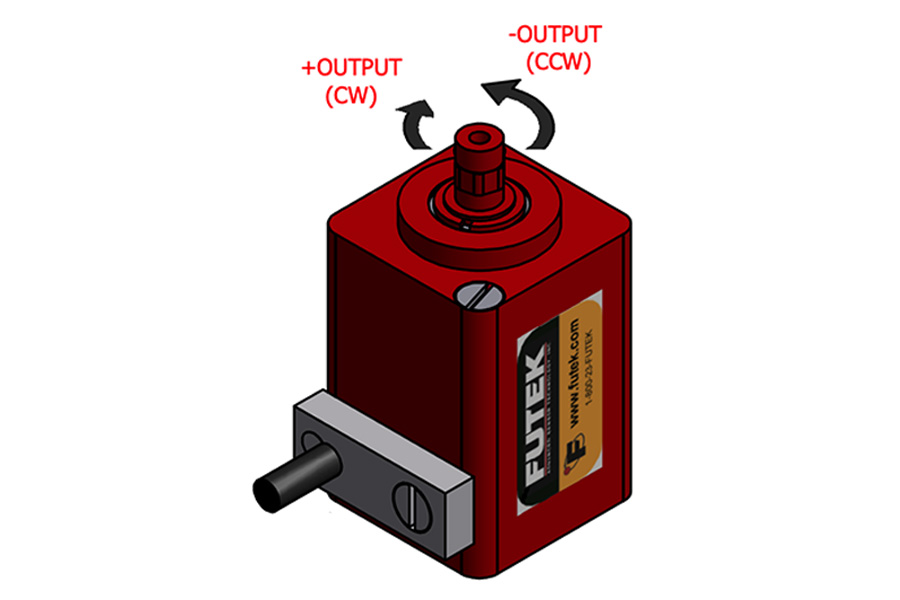

Non Contact Rotary Torque Sensor with shaft ends and mounting support can be used as functional check on tilt procedure or rotation monitoring. With the option of changeable mounting positions, applications for left and right hand torque readings as well as the static and dynamic conditions are possible.

TRS705 Rotary Torque Sensor Non contact shaft to shaft with Encoder

A line of non-contact, rotary, transformer, shaft torque sensors ideal for test installations running long-term durability testing. Extended speed and more.. The range of Specialty non-contact rotary torque sensors adaptable for use for special applications have been developed for include hydraulic pump testing, hydraulic motor testing.

Noncontact rotary torque sensor for motor torque measurement

The SRM torque has highly non-linear variations with rotor position and current, and thus, it's very challenging to obtain an accurate analytical expression [26], [27], [28]. Therefore, in this work, the motor torque data is obtained using finite elements method (FEM) and then these data are verified experimentally using static torque transducer.